Successful outsourcing starts with the right collaboration partner.

The best basis for outsourcing product development and production processes is trust. Our many years of experience and a continuously growing portfolio of upmarket clients are a good start. Our customers value our close collaboration, with the common goal of achieving the best result.

Outsourcing to bags and more enables you to reduce costs and effort, save time, avoid capacity bottlenecks and ensure consistently high product quality.

We can offer you each segment of development and production as a separate entity.

Here’s an overview of our service modules:

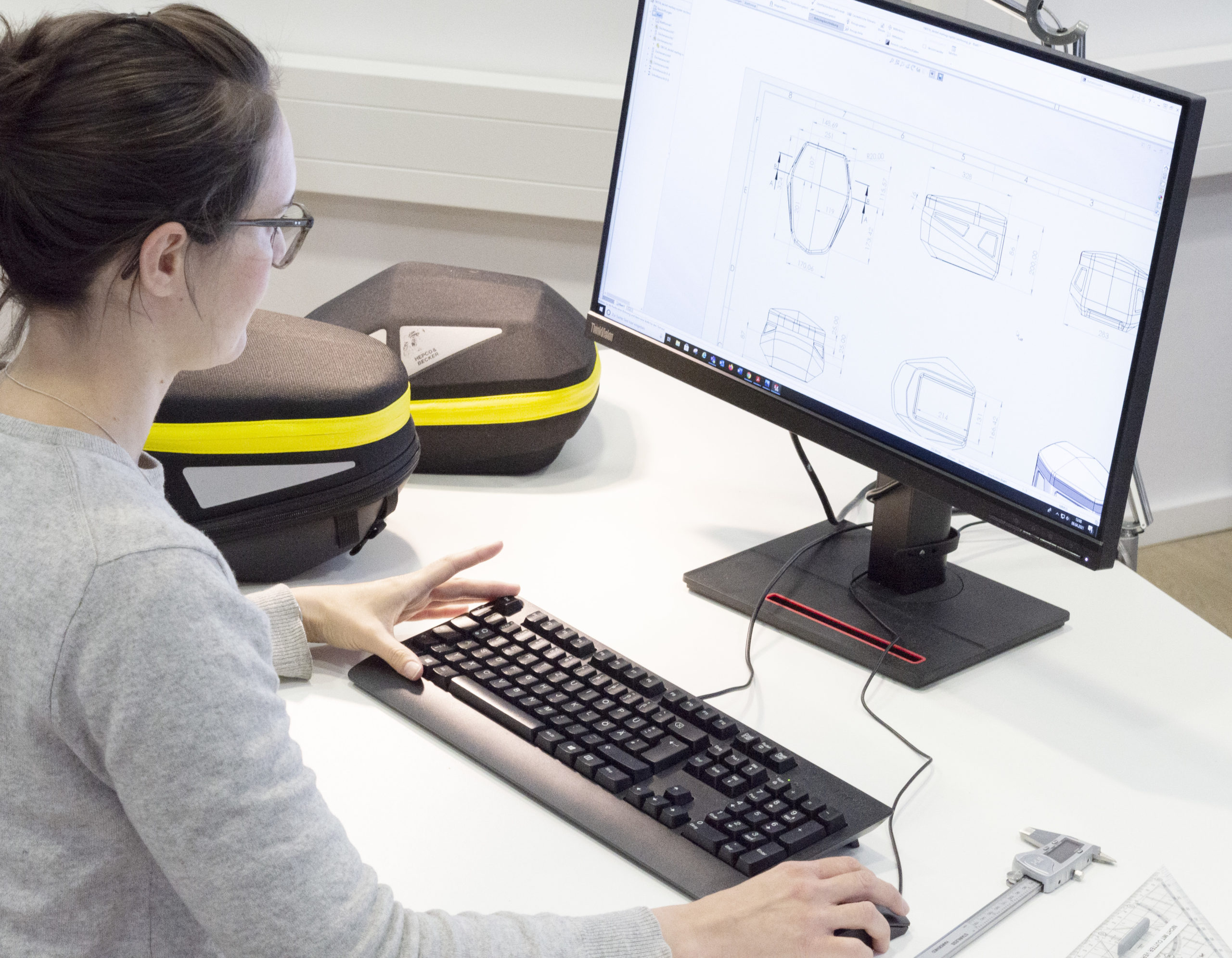

Product design

- Market and competition research

- Materials research

- Moodboards, sketches

- CAD models, renderings, 3D shape models

- Continuous coordination with Product Engineering

- Creation of product graphics

- Ergonomic adaptation

- Ongoing consultation with Production

Product development

- Creation of a requirements profile

- Mock-up and building of a prototype (CAD-supported)

- Analysis of function and practicability

- Test series (functional and material testing)

- Production preparation

- Constant quality management (from prototype through to mass production)

- Obtaining the required approvals, where necessary (TÜV/GS Seal or CE Norm)

Production

- Materials research and analysis

- Selection of reliable suppliers

- Selection of reliable, quality-conscious production partners

- Approval of production samples

- Series production

- Regular quality checks (also on-site)

Supply chain management

- Production planning

- Production and final quality assurance

- Customer-specific packaging

- Handling of global logistics (EXW, FCA, FOB, DDP)

- Storage in Germany with weekly series delivery (JIS)

- Interim storage

- All logistics processes can be managed

Product design

- Market and competition research

- Materials research

- Moodboards, sketches

- CAD models, renderings, 3D shape models

- Continuous coordination with Product Engineering

- Creation of product graphics

- Ergonomic adaptation

- Ongoing consultation with Production

Product development

- Creation of a requirements profile

- Mock-up and building of a prototype (CAD-supported)

- Analysis of function and practicability

- Test series (functional and material testing)

- Production preparation

- Constant quality management (from prototype through to mass production)

- Obtaining the required approvals, where necessary (TÜV/GS Seal or CE Norm)

Production

- Materials research and analysis

- Selection of reliable suppliers

- Selection of reliable, quality-conscious production partners

- Approval of production samples

- Series production

- Regular quality checks (also on-site)

Supply chain management

- Production planning

- Production and final quality assurance

- Customer-specific packaging

- Handling of global logistics (EXW, FCA, FOB, DDP)

- Storage in Germany with weekly series delivery (JIS)

- Interim storage

- All logistics processes can be managed

We’re proud of our loyal customer base.

Leading premium brands from exciting sectors rely on our wealth of experience. Our extensive bags and more portfolio of services offers a tailored solution for every brand. From consulting to a 360° service.

Automotive

Motorbike

Sport

Lifestyle